- News and Events

- News

- Dinex and Kohler Mutual Journey to Stage V

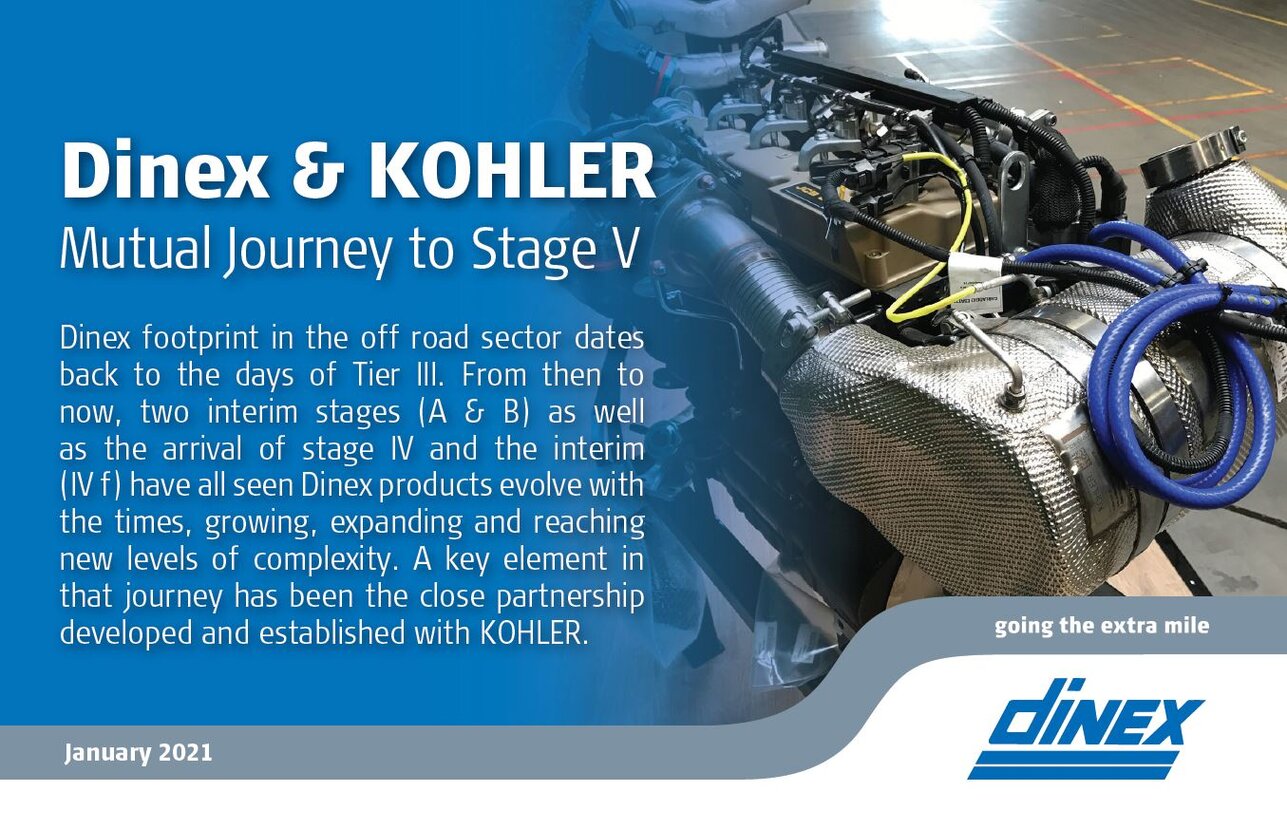

Initially through KOHLER’s Lombardini brand, Dinex has supplied thousands of Diesel Oxidation Catalysts (DOC) for the KDI range of engines 1,9-2,5 and 3,4 ltrs, Tier IIIB compliant. A precedent of simple design, excellent service and supply flexibility was set, paving the way to further cooperation. The road to Stage V started with the introduction of particle number regulations. This step in the regulation created the need for the addition of Diesel Particulate Filter (DPF) to the aftertreatment system design. With this in mind Dinex and Kohler engineering group, in Reggio Emilia (Italy), teamed up to create a solution to meet the Stage V legislation limits. The results of this collaboration was a modular, scalable and serviceable system, able to adapt to different vehicle layouts and configurations, a flexibility requirement of the utmost importance in off road applications.

The scope of supply was the complete stage V system (for below 56kW engines) including: The coating of cordierite DOC and DPF, canning, insulation, front pipe, V-clamps, gaskets, support brackets and front pipe with decoupling element. With a development cycle of 3 years, the concept development included CFD simulations to assess design, flow, pressure drop and thermal management aspects.

Extensive testing was conducted at Dinex’s laboratories ranging from SGB to engine bench testing to evaluate emission performance and endurance of the DOC-DPF concepts. Thorough FEA testing was also conducted to ensure all mechanical durability aspects surrounding the very different designs and components involved were accounted for.

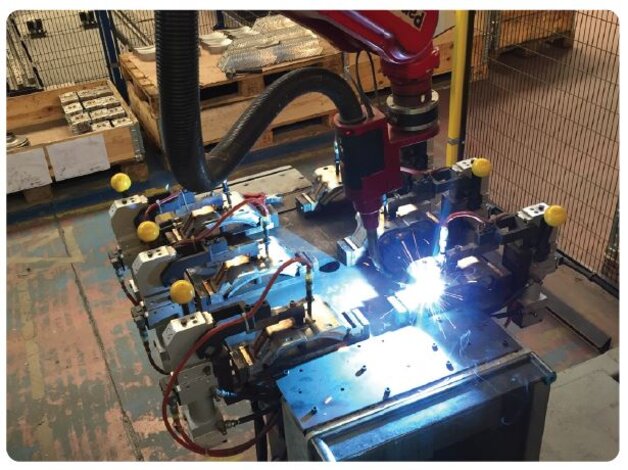

A state of the art production process was designed and built in two locations to have a smooth flow from the coating of the catalysts components to their assembly into the final product along with all other components. Fully automated lines with capacity for 20.000 units with advanced coating and welding equipment as well as Dinex’s signature integrated insulation technique, result in a product of the highest quality that is capable of complying with the very tough technical requirements

of the project.

A true example of Dinex’s commitment to high quality engineering, with closely involved teams in Germany, Denmark, Finland, Italy, and Turkey working together to provide KOHLER with a seemingly effortless service that is both agile and global.

Learn more about Dinex emission control solutions for off road applications, contact our CSO, Mr Lennart Rasmussen or our ATS Program Manager, Mr Mahipat Balwant Ranawat.